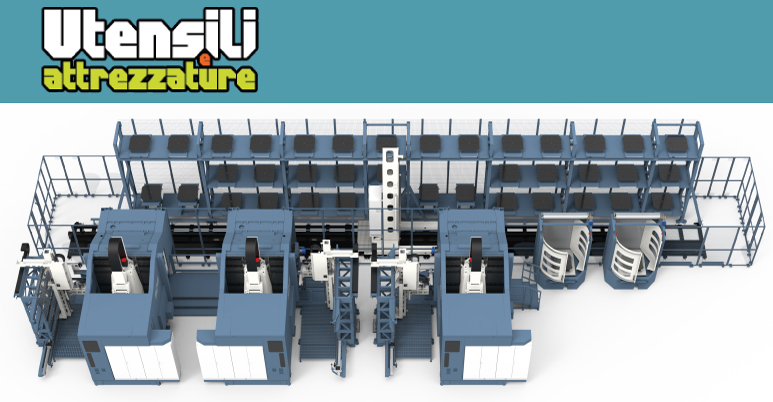

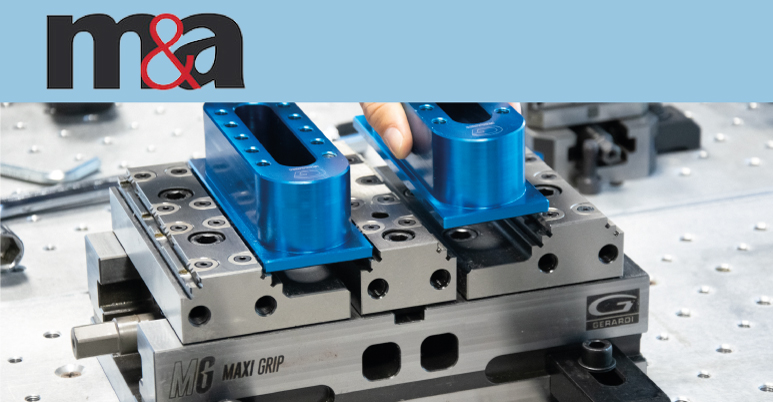

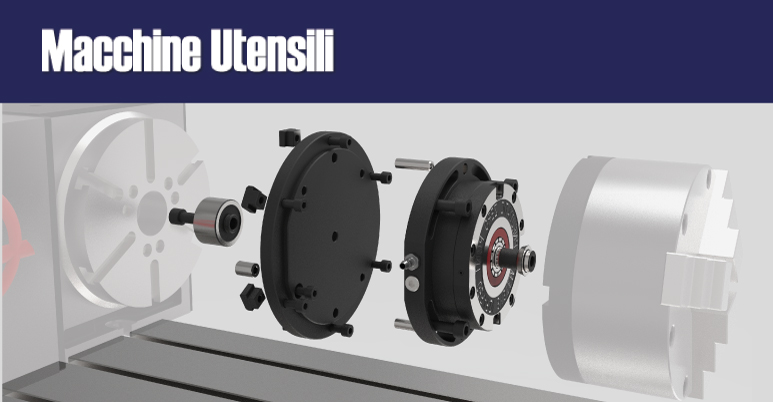

Milling and Turning in Combo.

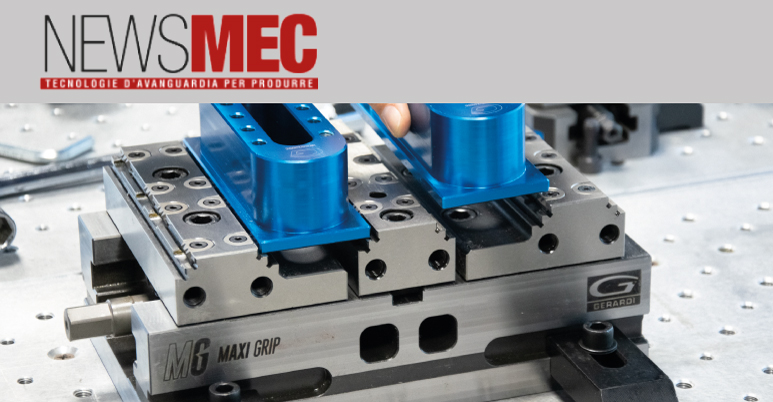

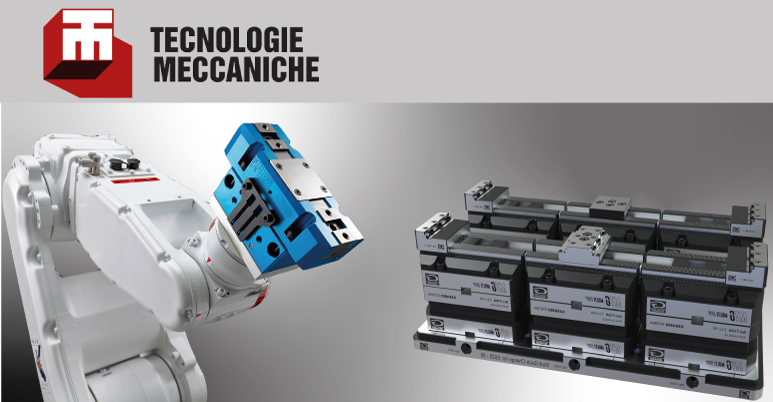

“Gerardi designs and realizes innovative solutions in the field of clamping and machine tools fixtures. Precise, reliable and of high performance systems realized with technologies in step with innovation, like the one of high automation which characterizes the new FMS system projected and realized by MCM.”

More than 200 coworkers, 15 million Euro turnover whose about the 65% exported in more than 70 countries all over the world. We are talking about Gerardi, an industrial group which can boast more than half-century of history, period during which it has been able to obtain and strengthen a reference role in the field of design, of production and distribution of clamping modular systems and equipments for milling, drilling and finishing of the workpiece on the machine tools.

Follow Us