Excellence in the DNA creates excellence for the market.

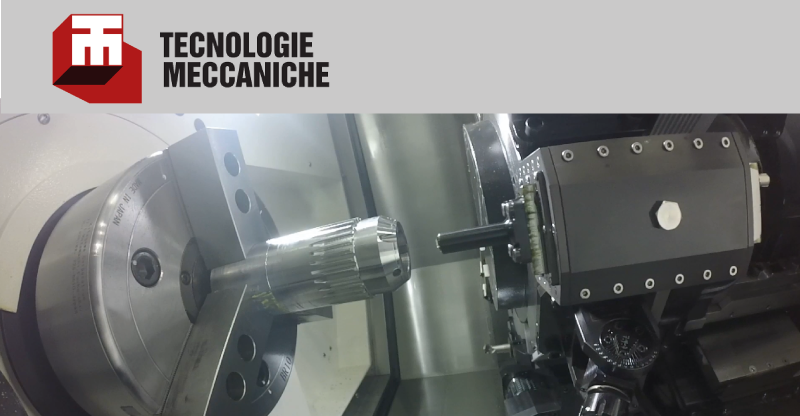

“A story focused on reliability as a strength that allows no compromises, from the beginning to the end of the production processes.”

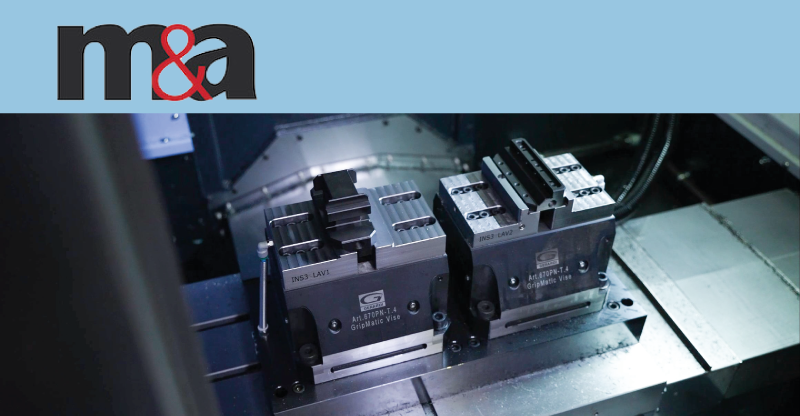

Constantly seeking the perfect balance between quality and the best quality/price ratio. Dynamic in interpreting the changes and general needs of its numerous international markets.

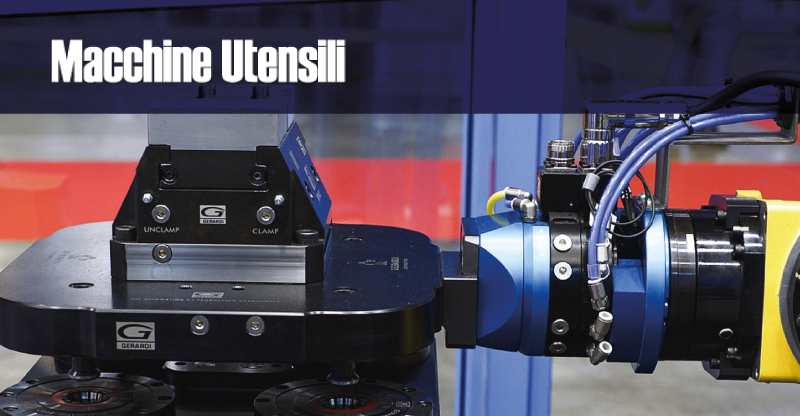

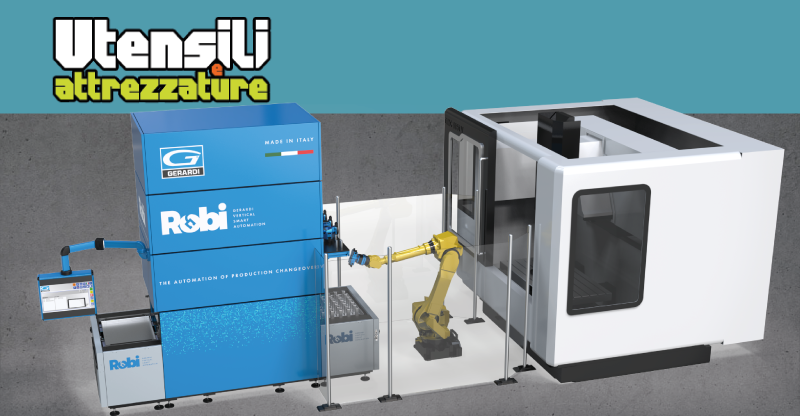

Gerardi is renowned for its ability to adapt to customer needs, customizing product and service strategies. Thanks to innovative, tailor-made solutions, it has achieved outstanding results, significantly improving the economy of its client businesses.

by Tecniche Nuove

Follow Us