Gerardi, Clamping flexiblity

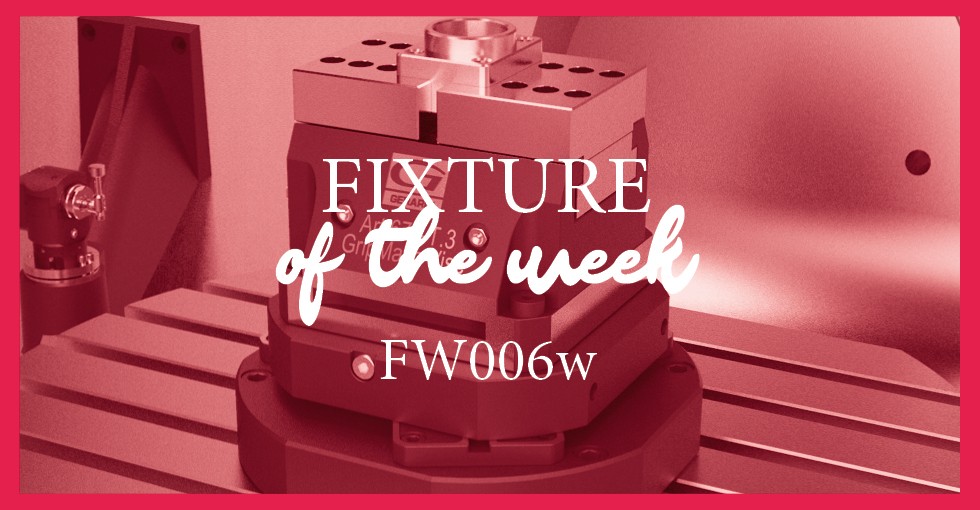

“Double Zero point comes from the need of clamping workpieces and fixtures of different shapes and dimensions on the same base plate.”

“Double Zero point comes from the need of clamping workpieces and fixtures of different shapes and dimensions on the same base plate.”

Automatic control of fixtures and workpieces. Mounting of the Automatic GripMatic vise on a Zero Point machine table made by a robot. Workpiece detectors and pressure sensors both on the clamping fixture and in proximity of the workpiece ensure the complete handling of the machining center for unmanned productions cycles.

“Gerardi company from Lonate Pozzolo (VA) chose modularity as a winning strategy to grow and develop worldwide. The company offers a complete range of products that includes both basic and high-level quality solutions but also special items, always ensuring the fixtures value and durability in time.

We have interviewed the General manager Mr. Ivano Gerardi”

Italian Mechanical manufacture is well-known and appreciated all over the world for its characteristics of high quality and an almost obsessive attention to the details.….

90° offset angle head with C4 output and 70bar internal coolant

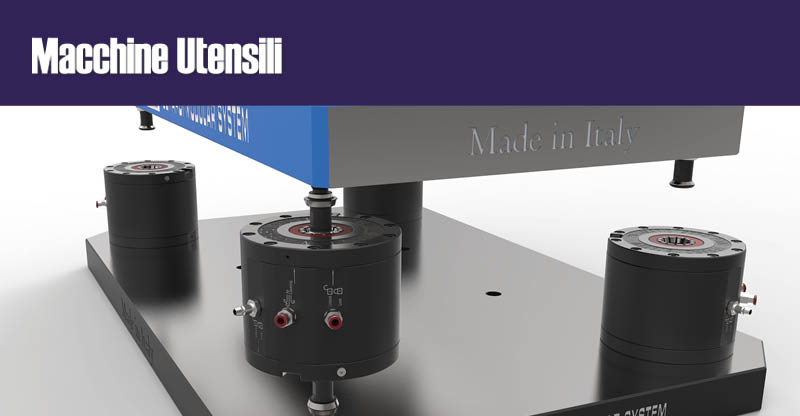

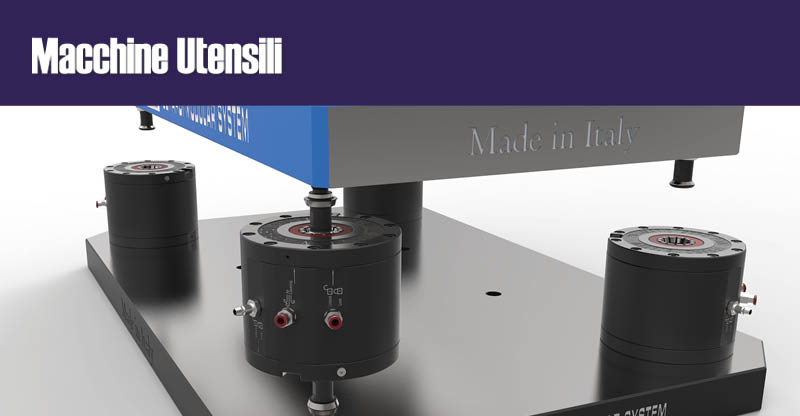

THE NEW GERARDI IMMEDIATE POSITIONING AND CLAMPING SYSTEM!

The Zero Point is an immediate positioning and clamping system, that represents the ideal solution for the positioning and the precise, fast and firm clamping of the equipments on the machine tools.The Zero Point is a system “NORMALLY CLOSED”, that uses die springs which allows the clamping of the pull-stud through the spheres located inside, while the filtered and lubricated compressed air enables the release only so there is no need to keep pipes connected constantly to the fixture.

—

50th HAPPY ANNIVERSARY SPECIAL OFFER

To celebrate our 50th anniversary, every month starting from January 250yj021 one surprise product offered with 50% saving! Do not miss the chance, stay tuned on our social networks, newsletters and website to discover the special products offered month by month!

NOW AVAILABLE ONLINE THE NEW WORKHOLDING 16 & TOOLING 03 PRICE LISTS AND CATALOGUES

We are glad to introduce our new Workholding 16 and Tooling 04 Price List and Catalogue 2021, now both available in the printed edition and online on the website www.gerardi.it

—

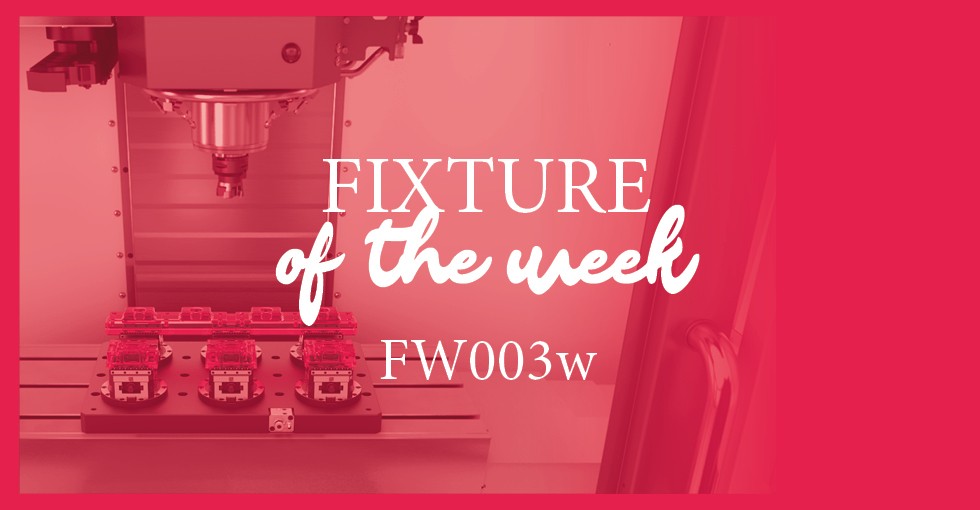

Base plate with 6 single Zero Point units and Compact Grip vises for the machining of small workpieces on vertical CNC

—

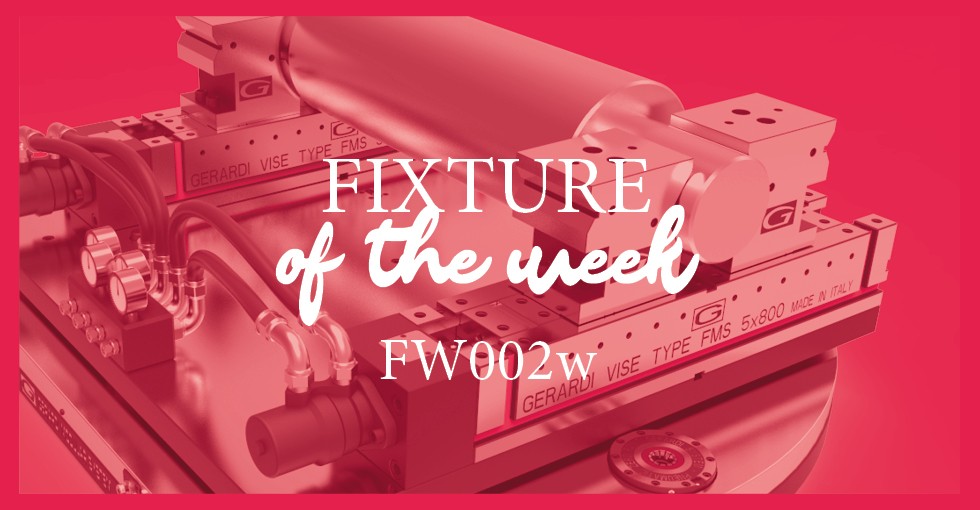

Mechanical clamping system for large round workpieces controlled by CNC hydraulic power unit

Follow Us