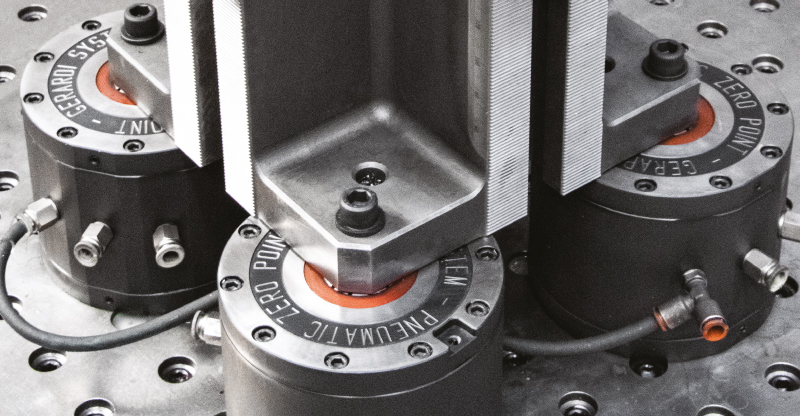

ZERO POINT SYSTEM

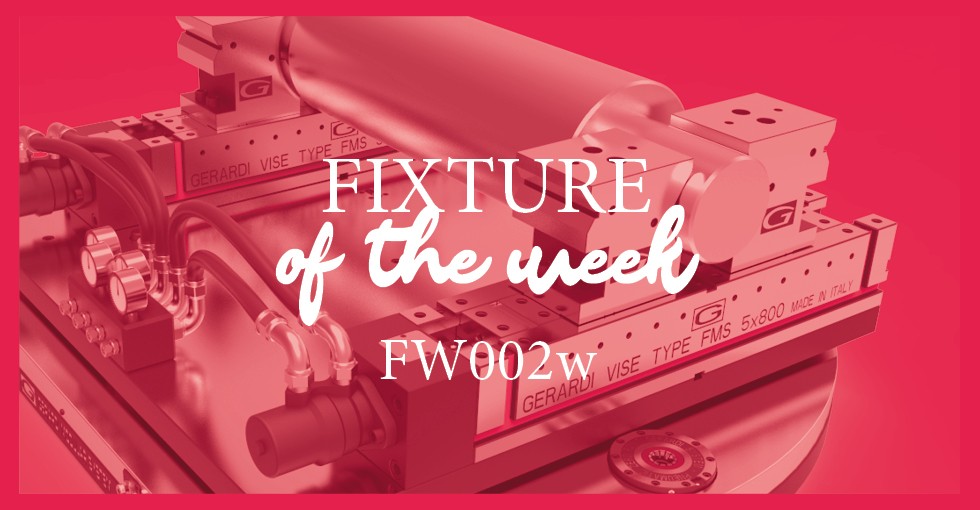

For our 50th anniversary only for February 2021 up to -50% on the Zero Point System

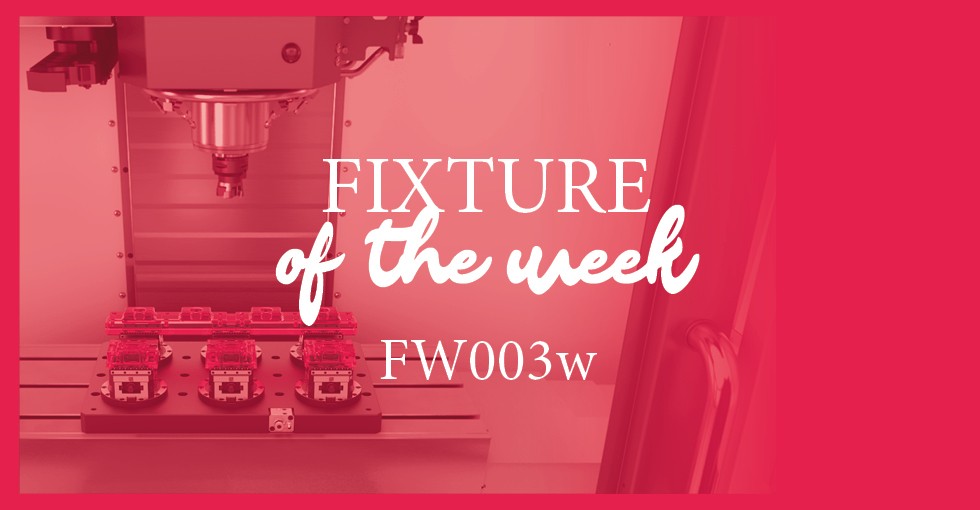

THE NEW GERARDI IMMEDIATE POSITIONING AND CLAMPING SYSTEM!

The Zero Point is an immediate positioning and clamping system, that represents the ideal solution for the positioning and the precise, fast and firm clamping of the equipments on the machine tools.The Zero Point is a system “NORMALLY CLOSED”, that uses die springs which allows the clamping of the pull-stud through the spheres located inside, while the filtered and lubricated compressed air enables the release only so there is no need to keep pipes connected constantly to the fixture.

—

50th HAPPY ANNIVERSARY SPECIAL OFFER

To celebrate our 50th anniversary, every month starting from January 250yj021 one surprise product offered with 50% saving! Do not miss the chance, stay tuned on our social networks, newsletters and website to discover the special products offered month by month!

Follow Us